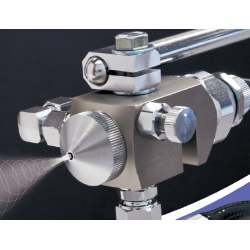

专业鞋底白乳胶喷涂喷枪/胶阀

- 产品描述

Pre-use Preparations:

Before attaching the spray gun, leaving air/liquid piping and hose switch open, use approx. 0.7MPa (100psi) air pressure to fully blow inside the piping and

hose to remove any particles, dust or other foreign matters which if not carefully cleaned out may cause trouble by blocking holes of the liquid nozzle or air cap.

Air Supply & Adjustment:

• Use Compressor, Piping, Solenoid Valve, Air Filter and Regulator with enough size and capacity consulting next table. In case air pressure decrease by low capacity equipments, piston will not work properly.• With a Piston drive air, be sure to use 3-port Solenoid Valve designed to allow release of secondary air into the atmosphere while the spray gun operation is stopped.(If 2-port Solenoid Valve is used, the liquid flow will not stop because the piston drive air is sometimes not discharged perfectly into the atmosphere even when spraying is stopped.)■ As shown in the drawing below, fit a Regulator and an Air Filter.Standard atomization air pressure can be used between 0.01 to 0.3MPa.When spraying a fine mist set air pressure higher, and when spraying a coarse mist, set the level lower.■ MS-8B has separately piton drive air inlet and atomization air inlet.Piston drive air moves needle valve to open and close liquid flow. If the pressure of piston drive air is set too low below 0.3MPa, Piston will not move, and liquid will not come out of the nozzle.Air pressure for piston drive air must be over 0.3MPa. Please use it between 0.3 to 0.5MPa.■ Spraying air volume is adjustable with #17 Atomization Air Adjuster.■ As shown in the drawing below, fit a Regulator and an Air Filter.Standard atomization air pressure can be used between 0.01 to 0.3MPa.When spraying a fine mist set air pressure higher, and when spraying a coarse mist, set the level lower.■ MS-8B has separately piton drive air inlet and atomization air inlet.Piston drive air moves needle valve to open and close liquid flow. If the pressure of piston drive air is set too low below 0.3MPa, Piston will not move, and liquid will not come out of the nozzle.Air pressure for piston drive air must be over 0.3MPa. Please use it between 0.3 to 0.5MPa.■ Spraying air volume is adjustable with #17 Atomization Air Adjuster.Spray Pattern Adjustment:

■ Adjustment of the quality to be sprayed is made by controlling the level of liquid pressure or by turning #15 Liquid Volume Adjuster. As turning the Liquid Volume Adjuster counterclockwise from zero point (fully turned condition to clockwise), quantity of liquid sprayed increases. After 8 turns, no liquid volume increase.■ Fully tighten the Liquid Volume Adjuster with #14 Locknut. If not, because of the piston movement and machine vibrations, the Liquid Volume Adjuster may get out of place.■ If a very small liquid quantity is desired to be sprayed, to make adjustment easier and less troublesome, it is recommended that Liquid Volume Adjuster of the MS-8B to opened up with a 1.0mm nozzle orifice rather than closed down with a 2.0mm nozzle orifice.• Use Compressor, Piping, Solenoid Valve, Air Filter and Regulator with enough size and capacity consulting next table. In case air pressure decrease by low capacity equipments, piston will not work properly.• With a Piston drive air, be sure to use 3-port Solenoid Valve designed to allow release of secondary air into the atmosphere while the spray gun operation is stopped.(If 2-port Solenoid Valve is used, the liquid flow will not stop because the piston drive air is sometimes not discharged perfectly into the atmosphere even when spraying is stopped.)• Use Compressor, Piping, Solenoid Valve, Air Filter and Regulator with enough size and capacity consulting next table. In case air pressure decrease by low capacity equipments, piston will not work properly.• With a Piston drive air, be sure to use 3-port Solenoid Valve designed to allow release of secondary air into the atmosphere while the spray gun operation is stopped.(If 2-port Solenoid Valve is used, the liquid flow will not stop because the piston drive air is sometimes not discharged perfectly into the atmosphere even when spraying is stopped.)

- 其它产品

联系我们

联系人:

Jason电话:

13538656018传真:

0755-88011080邮箱:

tonsens@foxmail.com